Mining is one of the oldest industries out there, but it has increasingly embraced high-tech methods as demand has increased. Plotlogic uses hyperspectral imaging, a technique generally found in labs and satellites, to add a new layer of data and automation to these crucial but often dated operations.

Hyperspectral imagery is basically a photo that captures light outside the visible range, allowing differentiation of substances that look the same to human eyes. As with pretty much everything else, nature got there first: birds and insects can see wavelengths we can’t, for a start, and it changes their entire view of the world.

We’ve adopted the idea in a variety of circumstances: It’s ultimately a form of spectral analysis, where you bounce radiation off an object and see what’s reflected or absorbed. Every substance has its own spectral signature, from skin to cement to rare earth minerals. The latter category is obviously where Plotlogic is aiming.

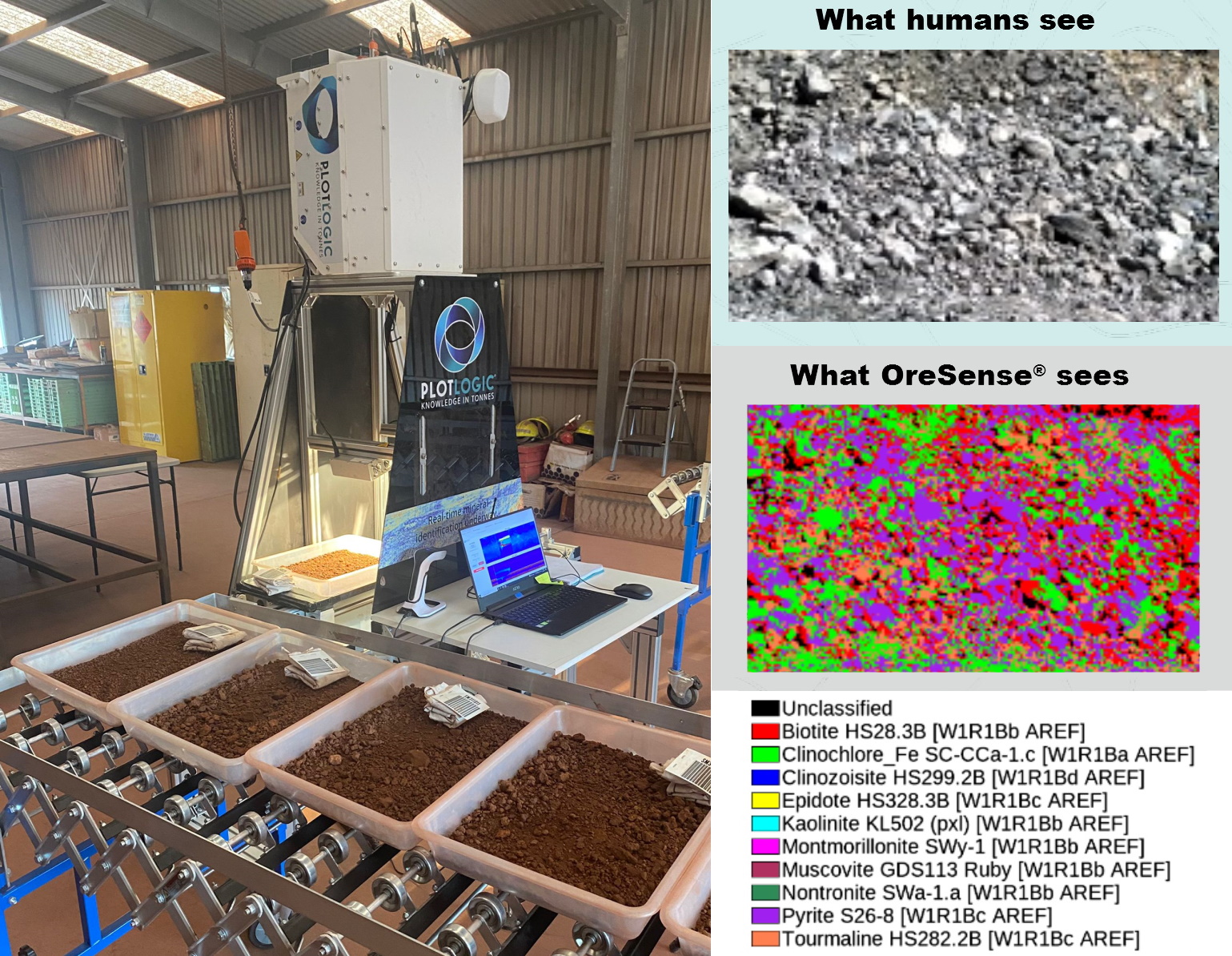

Founded in 2018 in Brisbane, Australia, Plotlogic makes a multispectral-plus-lidar imaging setup that looks at a pile of rubble extracted from a mine and says, “there’s some lithium, there’s a bit of silver, there’s some sulfur.” (Though I seriously doubt those three will be found in the same pile.)

Of course mines already do this sort of analysis at some point. Otherwise how would they know what to refine, truck out and so on? But this usually depends on taking samples to a lab and submitting them to — you guessed it — spectral analysis. Plotlogic is letting this crucial step take place on site, potentially making operations much more efficient.

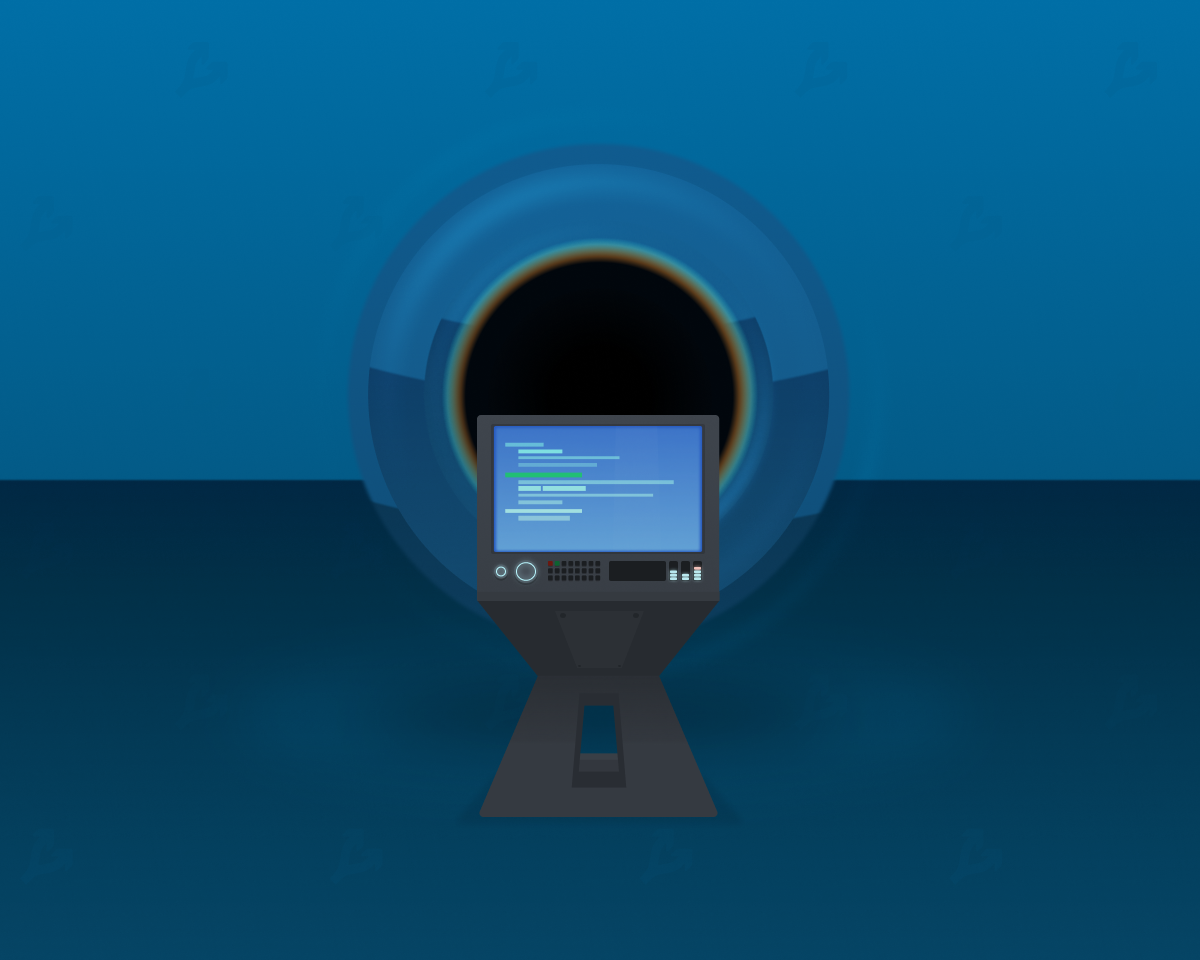

A stationary OreSense machine scanning ore samples, and an example of how those samples might be analyzed. Image Credits: Plotlogic

“That’s the real innovation here: embedding it into mining operations and empowering mine staff with real time information,” said CEO and founder Andrew Job.

The company first deployed its OreSense machines in 2019, and has been iterating on the product since, with feedback from major mining companies. It can be stationary or mobile, either scanning ore as it goes past on a conveyor belt or going to where it’s been collected. A version on treads allows navigation into locations that people can’t safely visit.

The system is designed to fit into existing mining processes, so there’s no need to redesign how you pull ore out of the ground or anything — and though changes do need to be made, they’re justified by increased efficiency, said Job.

“We see three types of benefits: financial, environmental sustainability and safety,” he explained. “The operation can process more ore and less waste, making it more profitable. They can be more precise, leaving more rocks in situ and not expending fuel and greenhouse gases moving waste. And finally, it reduces human exposure hours in the mine.”

We may have moved past the days of black lung but mining is still a fundamentally challenging and dangerous job. The less time workers are around heavy machinery, enclosed spaces and air filled with powdered rock, the better. Having reliable and rich imagery could also help usher in autonomous mining sooner rather than later, Job suggested.

The $18 million A round was led by Innovation Endeavors, with participation from BHP Ventures and Touchdown Ventures — both venture arms of major mining groups — as well as DCVC, Baidu Ventures and Grids Ventures. The plan is to use it to expand commercial deployments and begin working internationally.

English (US) ·

English (US) ·